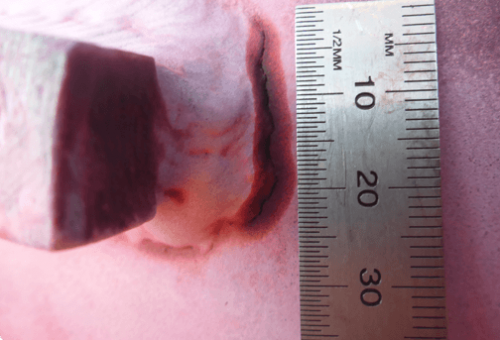

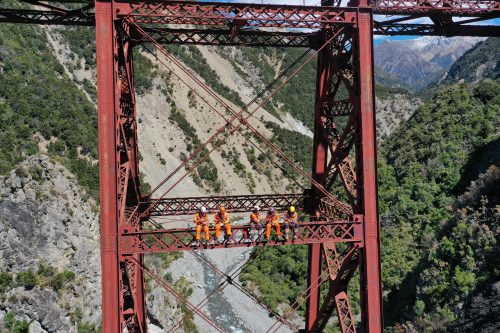

Deterioration of concrete structures can become a real challenge for the owners and cost significant amounts in remediation and repair if not identified and dealt with early. Abseil Access provides comprehensive inspection of concrete structures and detailed reports to enable our clients to manage their assets or structure’s integrity proactively.