Corrosion and degradation of substrates occurs when the selected coating protection system begins to fail. Coatings are comprised of a complex mixture of raw materials applied to provide protection from the elements and other environmental factors.

Corrosion and degradation of substrates occurs when the selected coating protection system begins to fail. Coatings are comprised of a complex mixture of raw materials applied to provide protection from the elements and other environmental factors.

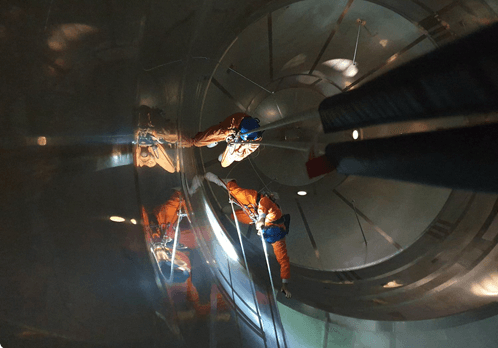

The Abseil Access team provides coating remediation services on at height structures to ensure the continued protection of our client’s assets. Over the years, Abseil Access have completed large scale projects on lighthouses, shipping channel markers, silos, towers, industrial, communication, and marine infrastructure.

Deterioration of concrete structures can become a real challenge for the owners and cost significantly if not identified and dealt with early.

Abseil Access provides ongoing condition monitoring with repairs and remediation to concrete structures, often at height and inaccessible areas.

The Abseil Access maintenance division has worked on a wide range of structures across multiple market sectors, including bridges, high-rise buildings, lighthouses, silos, hydro stations, chimneys, dams, and industrial and communications infrastructure.

Our team has provided safe, efficient, and innovative maintenance and repairs solutions underpinned by rope access and specialist access systems.

The Abseil Access dairy maintenance teams include rope access and multi-skilled tradespeople who provide intelligent solutions to routine or complex asset maintenance activities.

Our equipment and personnel comply with strict hygiene requirements for food processing plants and strict sterilisation protocols upon completion of each project.