Hydroelectric or hydroelectric energy has been a part of New Zealand’s energy system for over 100 years, providing more than half of the country’s electricity needs. Hydroelectric energy and our hydro stations are currently the primary renewable energy sources in New Zealand, and frequent inspection, repair, and ongoing maintenance are key to protecting our energy sources.

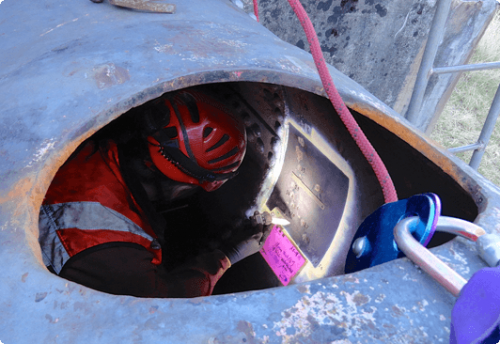

Penstock Inspection

Penstocks are pipes or long channels that carry water from the hydroelectric reservoir to the turbines, making them critical infrastructure. Abseil Access has provided specialist services to maintain penstocks for major hydro facilities and clients across NZ, including Meridian Energy & Trust Power NZ, since 1996.

- Confined Space Entry (CSE)

- Industrial Rope Access

- Concrete Condition Inspection

- Coating & Corrosion Surveys

- Cathodic Protection Surveys

- Non-Destructive Testing (NDT)

- Concrete & Coating Remediation

- Anode Replacement

- Spillway Inspection & Maintenance

- Shutdown Service & Support

Penstock Specialist Access Services

Abseil Access offer comprehensive specialist access services to penstocks and hydro facilities, including industrial rope access and confined space entry (CSE). Since 1992, the Abseil Access team has provided specialist access solutions to the hydroelectric market, such as surveying, NDT and inspection, industrial maintenance, and current cathodic protection and coating repairs.

Penstock Integrity Inspection

Deterioration of concrete or coating protection systems in penstocks can quickly become a real challenge for hydroelectric plant operators, costing significant amounts in remediation and repair if not identified and dealt with early. Abseil Access provides comprehensive inspection of concrete and steel penstocks, as well as detailed reports and recommendations to enable our clients to manage the integrity of their assets or structures proactively.

Our Group’s inspection pedigree, access services, and concrete or coating protection maintenance capabilities ensure the Abseil Access team can provide safe, high-quality, and cost-effective solutions for penstocks.

Penstock Remediation & Repair

Corrosion, erosion, and degradation of steel and concrete penstocks can occur for various reasons, such as incorrect application, wear, surface damage from scouring, or lack of cathodic protection.

The Abseil Access team has provided a range of magnesium sacrificial anode installations, coating surveying and remediation, and concrete inspection, maintenance, and repair services to penstocks across New Zealand to ensure our client’s assets’ continued protection and operations.

Case Studies